Ready Mix Quality Control

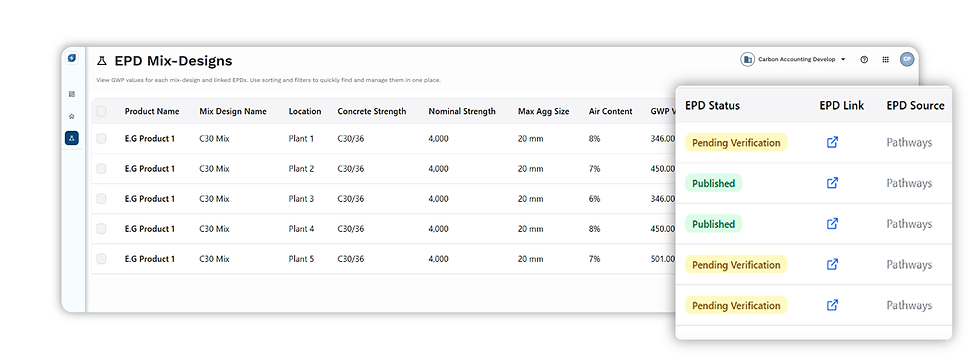

Command Cloud EPDs

Where Sustainability Meets Productivity

Provide clear, credible data on your mixes to customers, regulators, and investors.

-

Identify operational carbon hotspots

-

Optimize mix designs

-

Lower emissions and expenses

-

Strengthen relationships and reputation

Ready Mix Quality Control

Load Assurance

In-Transit Slump Monitoring Helps Prevent Rejected Loads

Capture visibility into exactly what’s going on inside the drum of your ready mix truck. Be in the know all the way to the jobsite on Slump, Temperature, W/C Ratio, Water Added, Drum Speed, and Volume.

-

Track real-time concrete properties and calculate water/cement ratio throughout the delivery cycle

-

Provide immediate feedback to production and dispatch to improve future loads and deliveries

-

Capture historical data to optimize mix designs and improve your carbon footprint

Ready Mix Quality Control

COMMANDqc

You Can Make Quality Control Profitable

Demonstrate that your raw materials conform to supplier and customer requirements. Optimize concrete mixes to comply with strength, durability and aggregate grading requirements while controlling mix costs.

-

Optimize each pour while controlling mix costs

-

Produce professional submittals in a fraction of the time

-

Put and end to out of tolerance loads